Steve Makowicki hangs wiring components.

Northridge Metal Fabrication invests in modernizing former Kaines West Michigan

By Rob Alway, Editor-in-Chief

LUDINGTON — In April 2022, Les Kaines sold his business, Kaines West Michigan, after operating it since 1965. The company was purchased by Brad Graham and Brian Cole, who each operate manufacturing businesses in Walker near Grand Rapids. They renamed the Ludington company Northridge Metal Fabrication.

Located at 211 E. Dowland St., the Northridge Metal Fabrication designs and manufactures custom fixtures and displays for the retail industry. Its largest vendor is Walmart.

The new fiber laser cutter was a $700,000-plus investment.

Several of the shelving units found in Walmart, particularly, are likely manufactured at Northridge. Many of the items are completed units sold direct to the retailer while others are components that sold to third party manufacturers who then sell the final product to the retailers.

Several of the shelving units found in Walmart, particularly, are likely manufactured at Northridge. Many of the items are completed units sold direct to the retailer while others are components that sold to third party manufacturers who then sell the final product to the retailers.

While many of the Northridge (and formerly Kaines) products are part of display systems in retail stores, one of the most visible products they manufacture can be found at the front entrance of any Walmart store, the cart sanitation wipes holder.

“Those holders are made here at our plant in Ludington,” General Manager Jim Marrison said. “We designed them and we manufacture them.”

Kaines West Michigan had its start on James Street. In the early 1980s it moved into its present location. Marrison said the new owners have been a good fit for the company and have made major investments toward assuring it continues to be a productive business that continues Les Kaines’ reputation of treating the employees well.

“Les was a very generous person to the employees,” Marrison said. “He always put his people first and that’s a tradition that we are continuing.”

Northridge currently employs 55 people. That number will often increase to over 75 in the busier summer season. The plant is operating two shifts with employees working 10 hour days, four days a week. Many of the employees have been with the company for several years, some over three decades.

“We are in the process of increasing wages,” Marrison said. “We have some great employees who have been with us for many years. Their knowledge of the equipment and manufacturing processes here is invaluable. As we modernize our equipment, they require less hands-on skills and more technical skills. We are committed to hiring people who stay with us long-term and learn those skills.”

Terry Stock works in the plant’s wood shop.

Marrison has been general manager of the company since 2021. He originally started at Kaines in 2000 until 2005 when he left for five years, returning in 2010. His background includes sheet metal and tool engineering and design.

These cart sanitation wipe holders are purchased by Walmart.

Owner Brad Graham also owns Design Manufacturing in Walker, which is a manufacturer and printer of point of purchase display and signage products, specializing in fabrication of plastics, wood, and metal. Owner Brian Cole owns Sightline Display in Walker, which specializes in designing and manufacturing retail displays.

One of the biggest recent investments has included a laser metal cutter that allows the plant to perform the work in-house.

“This machine, called a fiber laser cutter, with all its components, was a $700,000-plus investment,” Marrison said. “Previously, we would spend over $1 million a year farming this service out to plants in Grand Rapids, which would often take several weeks for turn-around. While we are still incurring labor costs with the new machine, we are able to provide better customer service by speeding up production.”

The machine is capable of cutting 5-foot by 10-foot sheet metal 3/4 inch thick. It uses high efficiency LED lights. Previous models used carbon dioxide, which used more energy.

“We have made a lot of efforts to become more energy conscious here,” Marrison said. “This is something that many of our vendors, especially Walmart, require. When we purchase new machinery, we are always considering the energy efficiency. Recently we replaced all our lights with LEDs.”

The recent investments are part of a commitment to keeping the plant operating locally, Marrison said.

“Brad and Brian are committed to keeping this plant running and growing,” Marrison said. “They have made a considerable investment in modernizing this plant and making it more energy and labor efficient.

“Our goal is to eventually move into a larger facility so we can increase our workforce and increase production.”

This story and original photography are copyrighted © 2023, all rights reserved by Media Group 31, LLC, PO Box 21, Scottville, MI 49454. No portion of this story or images may be reproduced in any way, including print or broadcast, without expressed written consent.

As the services of Media Group 31, LLC are news services, the information posted within the sites are archivable for public record and historical posterity. For this reason it is the policy and practice of this company to not delete postings. It is the editor’s discretion to update or edit a story when/if new information becomes available. This may be done by editing the posted story or posting a new “follow-up” story. Media Group 31, LLC or any of its agents have the right to make any changes to this policy. Refer to Use Policy for more information.

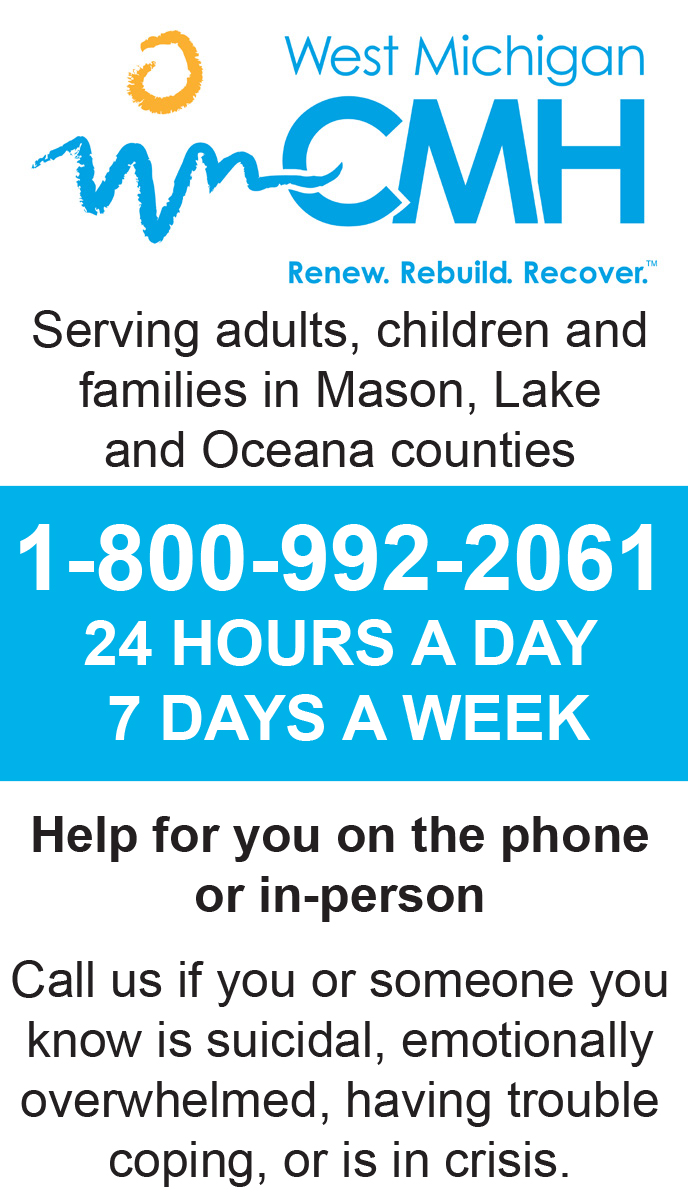

Please consider helping to fund local news. Mason County Press and Oceana County Press are available for free thanks to the generous support of our advertisers and individuals. Three ways to help us: Venmo: @MasonCountyPress; Paypal: MasonCountyPress@gmail.com; Mail a check to PO BOX 21, Scottville, MI 49454.

(1).gif)

.png)