Third order lens from Big Sable Point Lighthouse, front, and fourth order lens from Ludington North Breakwater Lighthouse, back.

By Rob Alway, Editor-in-Chief

LUDINGTON — The United States Coast Guard recently renewed its loan agreement of two Fresnel lighthouse lenses with the Mason County Historical Society. The lenses were originally used in Big Sable Point Lighthouse and Ludington North Breakwater Lighthouse and are on display at the Port of Ludington Maritime Museum, operated by the Mason County Historical Society.

The third order Fresnel lens from Big Sable Point Lighthouse was installed in the 112-foot tower, located in what is now Ludington State Park, when the structure was built in 1867. The lens was built by Sautter Lens Works. It was removed in 1985 and was placed on loan with the Mason County Historical Society. For several years it was located at Historic White Pine Village but was moved to the Port of Ludington Maritime Museum when it opened in 2017.

The third order lens is 4-feet, 8-inches in height with an inside diameter of 3-feet, 3-inches.

The fourth order Fresnel lens from Ludington North Breakwater Lighthouse was installed when the lighthouse was built in 1924. It was made by Macbeth Evans Lens Works.

It was removed in 1995 and replaced with a 12-inch Tideland Signal ML-300 acrylic optic. Like the Big Sable Point third order lens, it also was initially on display at Historic White Pine Village and is now on display at the maritime museum.

The fourth order lens is 2-feet, 2-inches in height with an inside diameter of 1-foot, 8-inches.

In 2016, the historical society received a National Maritime Preservation grant from the U.S. Department of Interior to restore the lenses. Funds from the grant along with local donations helped raise the over $100,000 needed to preserve the lights.

“We are honored to be entrusted by the Coast Guard to be the caretakers of these two historical Fresnel lenses,” said Rebecca Berringer, executive director of the historical society. “The lenses make up a cornerstone exhibit at the Port of Ludington Maritime Museum which demonstrates the diverse and rich maritime heritage of Mason County.”

Augustin-Jean Fresnel

Augustin-Jean Fresnel

Fresnel (1788-1827) was a French civil engineer and physicist whose research in optics led to the almost unanimous acceptance of the wave theory of light, supplanting Newton’s corpuscular theory. But, he is best known for his 1822 invention of the Fresnel lens, which is is a type of composite compact lens which reduces the amount of material required compared to a conventional lens by dividing the lens into a set of concentric annular sections.

The design allows the construction of lenses of large aperture and short focal length without the mass and volume of material that would be required by a lens of conventional design. A Fresnel lens can be made much thinner than a comparable conventional lens, in some cases taking the form of a flat sheet.

It is estimated that at least 75 Fresnel lenses are still in use in American lighthouses while another 400 still exist, including the two in Ludington.

The manufacturers

Louis Sautter

Sautter Lens Works

Louis Sautter (pronounced “So-tay) completed engineering school at the Central School of Arts and Manufacturers in 1846. He entered the navigation aids business in 1852 when he assumed ownership and management of a company originally started by Francois Soleil Sr. in Paris.

Sautter immediately began to improve on the lens designs that had been made by Theodore Letourneau, son-in-law of Soleil. Sautter introduced new construction methods and increased the quantity and quality of lens production.

His first lens sent to the United States was the third order lens made for Alcatraz Island near San Francisco, Cali. in 1853. The American Lighthouse Board split its purchases about 50-50 between Henry-Lepaute and Louis Sautter during the main conversion to Fresnel lenses between 1853 to 1860.

In 1870, the firm’s name was changed to Sautter, Lemonnier; in 1890, it became Sautter Harle; in 1910, it was renamed Harle & Cie; in 1915 it was Anciens Etablissements Sautter – Harle; and in 1970 it was sold to Alstholm Company.

Macbeth-Evans Glass Company

George Macbeth

The Macbeth-Evans Glass Company, based out of Pittsburg, was established in 1899 after a merger between the glass companies of George A. Macbeth and Thomas Evans. The company operated several regional offices but its most significant glass works was located in Charleroi, Penn.

Thomas Evans & Co. was formed in 1869. George A. Macbeth Co. was formed in 1872.

The company absorbed the American Chimney Lamp Co. and gained controlled of M.J. Owens’s patents on the Owens glass-blowing machine, as well as Hogans-Evans Company, making it, at the time, the world’s largest glass manufacturer.

In 1910, the Lighthouse Bureau approached Macbeth-Evans and requested that the company evaluate the possibility of producing a small fifth-order Fresnel lens for use on American lightships. Macbeth-Evans accepted the Fresnel lens project and started an evaluation of all parts of the design and construction of such lenses, as well as the composition and manufacture of the lens glass.

The glass used in all of Macbeth-Evans lenses was different from that used by the European makers. Macbeth-Evans used flint glass with an index of refraction of 1.55 versus the European crown glass standard of 1.52, and a density of 2.95 versus 2.52 for Europe. The glass was known as non-hygroscopic, meaning that it does not absorb any moisture. It was a heavy, brilliant flint glass with a very slight gray color, and it would take a finer polish than European crown glass. This type of glass was harder to make, especially without bubbles and striae.

Macbeth-Evans lenses were also improved over European lenses in their physical design. George Macbeth hired Professor Harry S. Hower, of the Carnegie Institute of Technology, to design the prisms used in his lenses. Professor Hower noted that in European prisms only one of the sides of the prisms was slightly curved, which improved its ability to direct the light as needed.

The Macbeth-Evans prism design was constructed with two conical surfaces and the third surface was a hyperboloid of revolution giving still more enhanced light throughput and control. This structure was more complicated than any other manufacturer had successfully produced, and Macbeth-Evans lenses were found to transmit as much as 50 percent more light than the European lenses of the same type and size.

The Macbeth-Evans prisms were manufactured completely by machine. The grinding and polishing equipment was developed by Mr. Heupel, the Macbeth-Evans manufacturing engineer, and allowed highly accurate and lower cost manufacture. Heupel also developed designs for all of the brass-work that was used to frame the finished lens panels. This brass-work was held to very high tolerances, which reduced the cost for the initial setup and testing of the lenses.

By the time Macbeth-Evans developed the capability to produce Fresnel lenses, the major lighthouse construction era had ended and there were few orders. Macbeth-Evans built very small quantities of Fresnel lighthouse lenses and a considerably larger number of buoy lenses, during the period from 1910 to 1932.

Macbeth-Evans also built most, possibly all, of the fourth-order range lenses used along the Panama Canal. It was the only U.S. manufacturer with these capabilities.

During World War I, most of the company’s production was dedicated to producing glass, particularly reflectors for searchlights for the army and navy.

The company was bought by Corning Glass Works in 1936 but continued to operate as Corning Glass Works Macbeth-Evans Division and later as Macbeth-Evans Division of Corning Glass Works in Charleroi, Penn. The plant was sold to World Kitchen in 1998. In 2018, the company was rebranded as Corelle Brands. In 2021, it merged with Instant Brands. Its headquarters are in Rosemont, Ill.

Officially, the lenses are cataloged by the U.S. government as US 18525 (Big Sable) and US 18530 (Ludington North Breakwater).

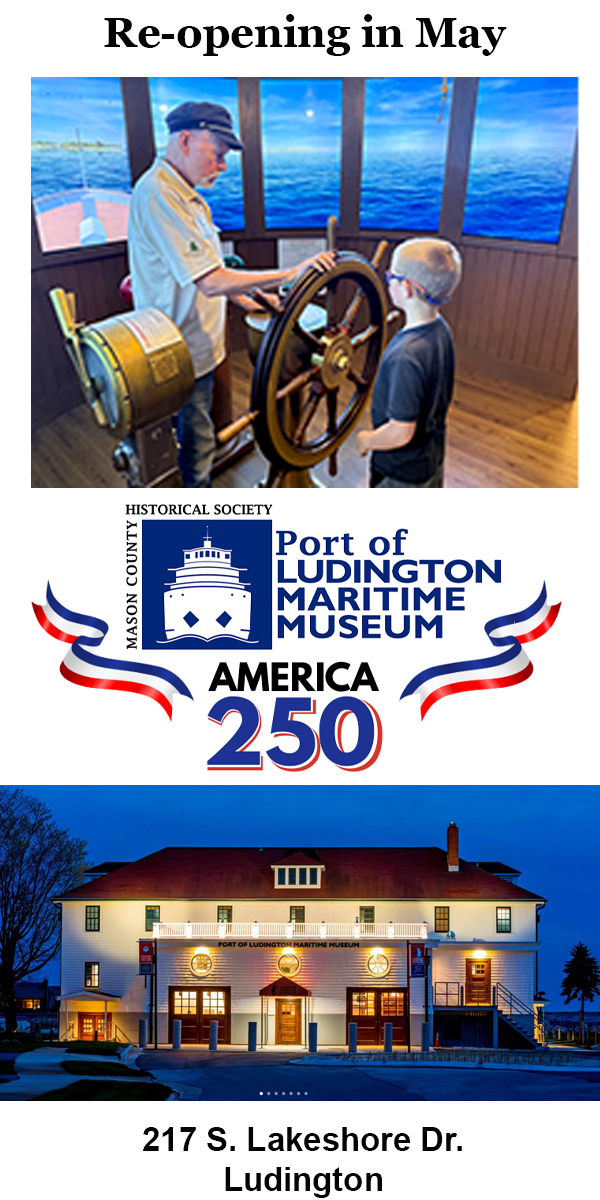

The lenses may be viewed at the Port of Ludington Maritime Museum, located at 217 S. Lakeshore Dr. Click here for more information and to view hours.

______________________________

Please Support Local News

Receive daily MCP and OCP news briefings along with email news alerts for $10 a month. Your contribution will help us to continue to provide you with free local news.

To sign up, email editor@mediagroup31.com. In the subject line write: Subscription. Please supply your name, email address, mailing address, and phone number (indicate cell phone). We will not share your information with any outside sources. For more than one email address in a household, the cost is $15 per month per email address.

We can send you an invoice for a yearly payment of $120, which you can conveniently pay online or by check. If you are interested in this method, please email editor@mediagroup31.com and we can sign you up. You can also mail a yearly check for $120 to Media Group 31, PO Box 21, Scottville, MI 49454 (please include your email address).

Payment must be made in advance prior to subscription activation.

We appreciate all our readers regardless of whether they choose to continue to access our service for free or with a monthly financial support.

_____

This story and original photography are copyrighted © 2025, all rights reserved by Media Group 31, LLC, PO Box 21, Scottville, MI 49454. No portion of this story or images may be reproduced in any way, including print or broadcast, without expressed written consent.

As the services of Media Group 31, LLC are news services, the information posted within the sites are archivable for public record and historical posterity. For this reason it is the policy and practice of this company to not delete postings. It is the editor’s discretion to update or edit a story when/if new information becomes available. This may be done by editing the posted story or posting a new “follow-up” story. Media Group 31, LLC or any of its agents have the right to make any changes to this policy. Refer to Use Policy for more information.

.png)